At Sagroparts, you will find a wide range of wear parts for bale presses. We have, among other things, chains, pick-up brackets, knives for the bale press, sharpening equipment, and much more. We offer wear parts for round-bale presses and bale presses for both large and small bales, including small bale presses and mini bale presses. Our wear parts for bale presses are designed to streamline your work and renew your parts when needed.

Bale Presses

Filter below:

Show filter

Active filters

Select category

Bale spear

Belts / Locks

Chains and gears

Grinding Equipment

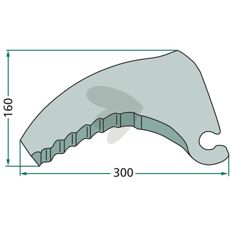

Knives for balers

Meter

Other Spare Parts

Pick-Up

Show products

Buy wear parts for bale presses online at Sagro

At Sagro, you can easily buy wear parts for bale presses online. We offer a comprehensive range of high-quality spare parts for round-bale presses, small bale presses, and all types of bale presses for hay. Whether you need new blades, belts, or other essential components, you will find what you need with us. Our wear parts are designed to maximize the lifespan and performance of your bale press, ensuring that your equipment always operates at its best. Order your wear parts conveniently from our online store and enjoy fast delivery right to your door.Can't find what you're looking for?

- Animal Husbandry

- ATV

- Batteries and Electrical Accessories

- Battery and Electric Tools

- Bearings

- Buckets and Front Loaders

- Cabin and Body

- Engine Heater

- Electric Fences

- Feeding and Watering

- Harvest and Haymaking

- Forestry & Wood

- Fuel and Exhaust

- Garden

- Green Area

- Hand Tools

- Lifting Equipment and Winches

- Lighting

- Hydraulics

- Hunting & Leisure

- Irrigation

- Oils and Chemicals

- Pneumatics

- Power Transmission

- Protective Equipment

- Soil Cultivation

- Snow Removal & Anti-Skid

- Spare Parts for Tractor

- Tractor Trailer

- Vehicle Lighting

- Weighing Systems

- Workshop Equipment

FAQ about Baler

A baler, also known as a round baler, functions by collecting, compressing, and binding forage crops such as hay and silage into dense, manageable bales. The machine gathers plant material from the ground and feeds it into a chamber where it is rotated and compressed into a bale. Once the bale reaches the desired size and density, it is bound with netting or plastic to hold it together. Finally, the bale is released from the machine for storage or transport.

The best round baler depends on specific needs and applications. Popular brands include John Deere, New Holland, and Krone, all of which offer models known for their performance and durability. Factors such as bale density, machine capacity, ease of use, and maintenance costs should be considered when selecting the best round baler for your farm.

The first round baler was introduced to the market in the 1970s. This innovation revolutionized how farmers handled hay and silage, making the process more efficient and less labor-intensive compared to traditional square bales. The round shape of the bales made them easier to transport and store.

The price of a baler varies significantly depending on the model, brand, and specifications. A new round baler can cost between approximately 150,000 SEK and over 500,000 SEK. Used balers are usually more affordable and can be a cost-effective option for smaller farms. For exact prices and offers, it is recommended to contact dealers or visit Sagro.se.

The cost of baling a round bale depends on several factors, including machine costs, fuel consumption, labor, and maintenance. Generally, the cost ranges from approximately 30 SEK to 50 SEK per bale. Owning a baler can be more cost-effective in the long run for larger farms compared to hiring baling services.

The price of a compactor varies depending on the type, capacity, and manufacturer. A basic household compactor can cost between 20,000 SEK and 50,000 SEK, while industrial models for agriculture or commercial use can range from 100,000 SEK to several hundred thousand SEK. For specific models and prices, visit Sagro.se or contact customer service.

When using reduced tillage, it is important to preserve soil structure and minimize disturbances. Techniques such as direct seeding or minimal tillage can help reduce erosion and retain moisture in the soil. Weed management becomes critical, making the use of cover crops and careful monitoring essential. Reduced tillage can improve soil health and long-term productivity by promoting biodiversity and increasing organic matter in the soil.